Chimney cowls are mounted on the top of chimney ducts. Their purpose is to prevent the chimney from downwind, rainwater and bird nesting, but most of all they are designed to generate chimney draught using force of the wind. Chimney cowls are designed to stabilize and increase chimney draught in ventilation and smoke ducts. In Darco offer there are rotary chimney cowls used to improve draught in ventilation ducts, self – adjusting chimney cowls that can be used for flue/smoke ducts, hybrid chimney cowls, that use force of the wind and, when it is not sufficient, electrical motor power, static chimney cowls and mechanical ones – draught generators.

Rotary chimney cowls are devices, which, in a dynamic way, use force of the wind to increase chimney draught. The turbine always rotates in the same direction no matter of the wind strength or its direction. They are to be mounted on gravitation based ventilation chimney duct endings.

Types of rotary chimney cowls:

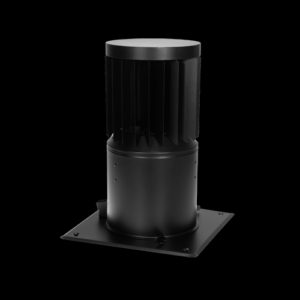

Hybrid Turbowent chimney cowls are devices, which, in a dynamic way, use force of the wind to increase chimney draught. They are also equipped with a low power brushless electric motor. When the wind speed is too small to achieve the desired efficiency, electric motor speeds the turbine up, when it is too strong it slows the turbine down. When the wind speed is strong enough to achieve the rotation speed set on the steering device, motor does not work, and cowl works just like the ordinary Turbowent.

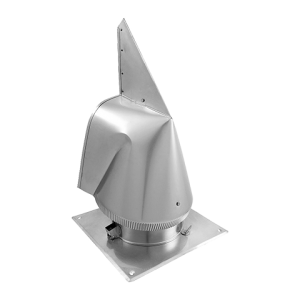

Self-adjusting chimney cowls use force of the wind to increase chimney draught. The cap always places itself in the opposite direction to the wind no matter of its strength or direction. They can be mounted on ventilation, flue (gas, oil) and smoke ducts.

Their principle is to increase and stabilize chimney draught no matter of what the chimney height, wind speed or other natural conditions are.

Construction of the cowls creates a pressure difference in their inlet – forcing the air in the duct to move up.