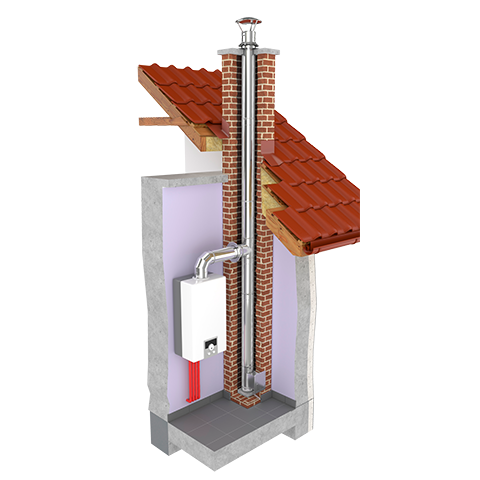

Darco system

CHIMNEY CLEAN OUT DOORS AND CLEAN-OUTELEMENT MOUNTING FRAME

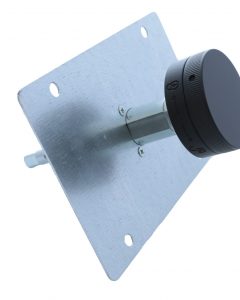

Chimney clean out doors – to cover the clean – out element of a chimney.

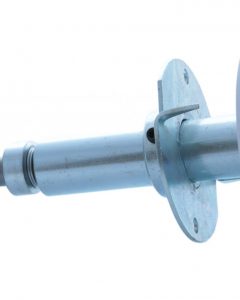

Clean out element mointing frame – mounting frame for doors and draught regulators RCW.

Chimney clean out doors are an aesthetical element covering the clean out element of a chimney system. Outer dimensions 205×225[mm] to a clean-out element channel of 125×185 [mm].

Clean out element mounting frame allows to mount the Darco-type cleaning doors as well as the RCW draught regulator in the Darco-type clean out element in a solid and durable way.

The clean out doors and clean out element mounting frame are made of chrome-nickel stainless steel. More information about dimensions and technical drawings – see catalogue card in “Downlad” tab.