Darco system

DRAUGHT REGULATORS

Do you want to pay less for your heating? Install a Chimney Draught Regulator- a device that serves to stabilise and reduce excessive underpressure in the flue pipes. Thus effectively reducing the fuel consumption of your stove.

Excessive underpressure in the chimney ducts can be caused by too big cross-sectional area of the flue pipe or temporary changes in atmospheric factors, e.g. gusts of wind. It is often impossible to say with certainty what the cause of excessive draught in the flue pipe is. However, the consequences are the same in all cases – inefficient combustion of the fuel the stove is powered with, and thus increased heating costs. In order to minimise additional expenses, it is worth using a Chimney Draught Regulator. Take a look at this short video, in which we present Chimney Draught Regulators.

The damper in draught regulator is designed in such a way that excess underpressure, exceeding the value set on the adjustment knob, would cause the damper to open, thereby providing additional air to the chimney. This will cause a reduction of the underpressure value in the chimney chamber:

- through cooling of the exhaust fumes,

- by increasing flow resistance – as the chimney, beside the exhaust, must also transport air

The change of the underpressure set on the draught regulator takes place by way of a change in the damper balance, with the use of the knob. The knob has a scale to set the underpressure. The label indicates the currently set underpressure value.

See how the Chimney Draught Regulator works:

Darco offers the following regulator types:

RCR – fixed onto the pipes – diameter range 120÷200 mm

RCO – round, diameters 80 mm, 150 mm

RCP – rectangular, for installation in assembly openings sized at 140 x 150 mm.

RCW – for installation in chimney inspection openings

RCO-EX – Chimney Draught Regulators with explosion safety system, which, in case of a sudden, significant pressure increase opens the regulator’s head, providing a route of escape for the chimney gases.

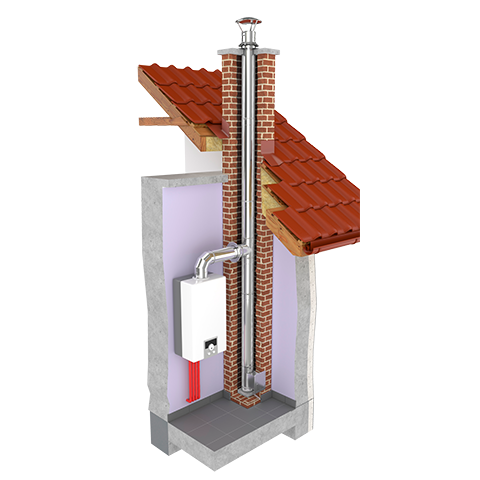

The appliance is designed to be mounted:

– on the flue connecting the stove to the chimney

– above the flue

– under the flue

Detailed information about the individual versions, materials used and technical drawings with dimensions can be found in the data sheet in the “downloads” section.