Darco system

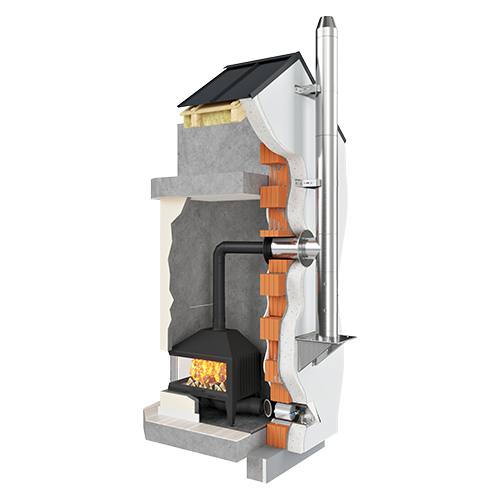

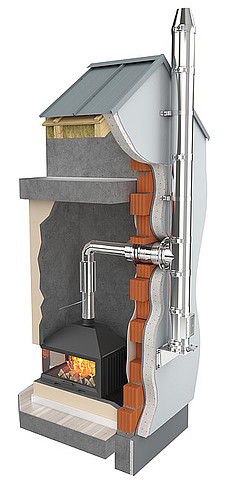

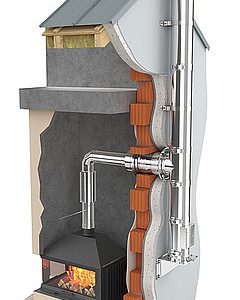

SPP-CHIMNEY CONNECTIONS FOR PELLETS STOVES

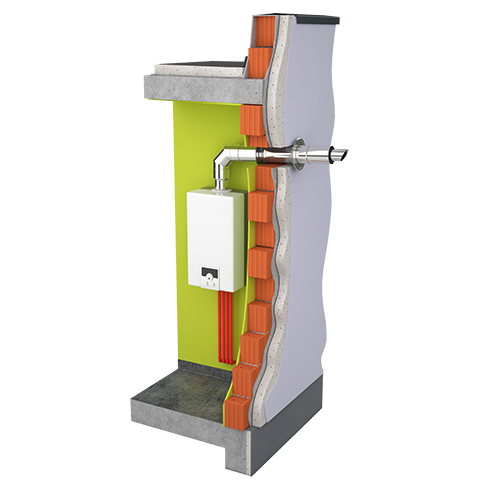

Recommended as fume extraction from heating appliances for pellets.

Chimney connections are made with mild DC01 steel sheet (in thickness 1,2 [mm]). It’s application is smoke extraction from pellet stoves. Elements are powder coated with heat resistant paint in black metallic color. Maximal temperature of constant work: 250°C.

Advantages:

- easy and simple mounting process

- high chimney tightness

- lower price than acid-resistant

- building chimney connections for pellets stoves

Usage

- as fume extraction from heating appliances for pellets

| Avaliable diameters: | 80, 100 [mm] |

| Material: | mild steel sheet type DC01 thickness 1,2 [mm] |

| Max. working temperature: | 250 [ºC] |

| Warranty: | 2 years |

More information – see catalogue card in “Download” tab.