COOPERATION

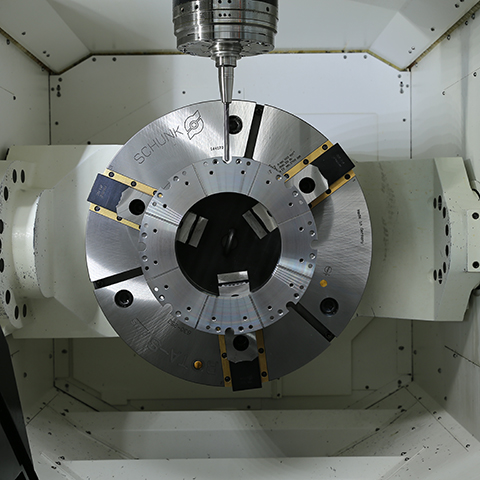

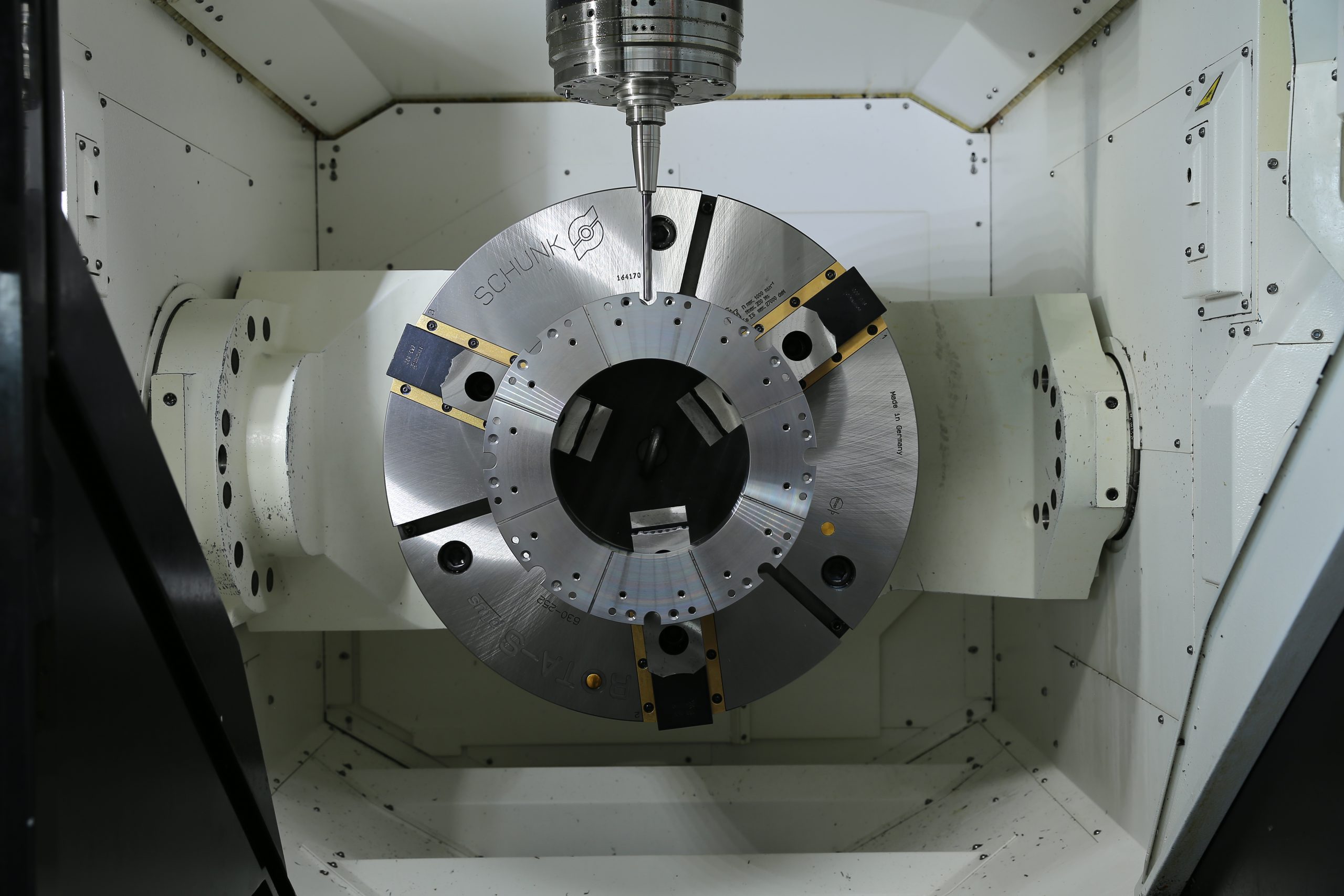

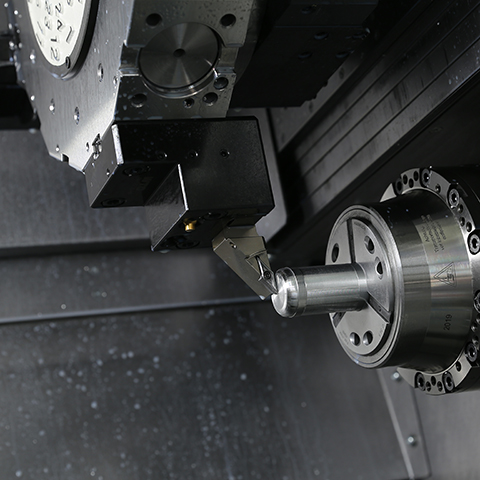

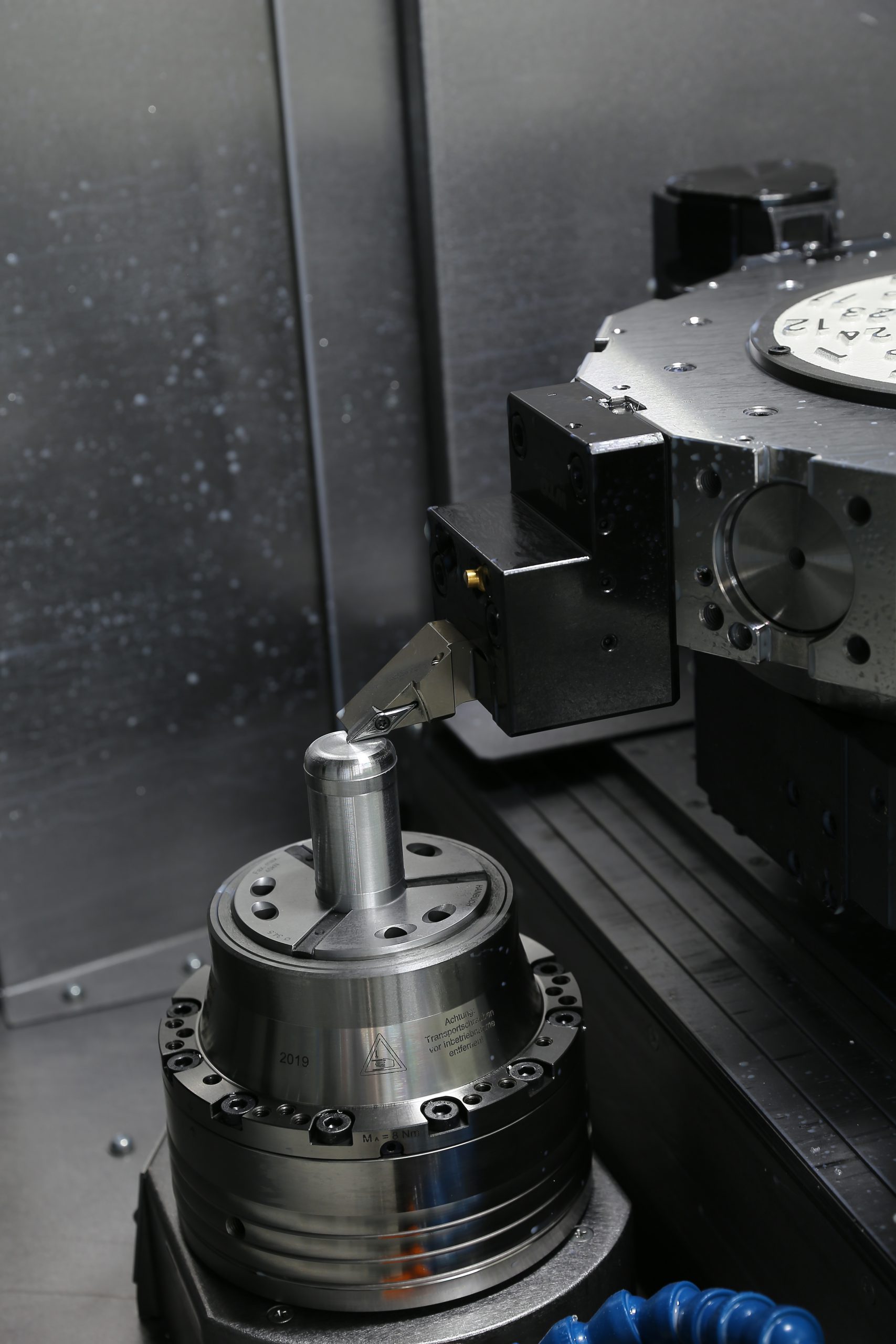

LATHES

It is a machining method in which the rotary movement is performed by the workpiece, while the feed movement is performed by a special tool – a turning knife.

Turning is the mutual movement of the tool and the workpiece. The workpiece, driven by the lathe’s spindle, performs a rotary motion. The tool performs an auxiliary feed movement. These movements overlap and add up. In the end, they achieve a previously planned machining target by turning.

We use it to roll:

CNC lathe – is a combination of conventional and numerical machine. This type of machine produces complex profiles in a constant quality, even with more pieces. It is characterized by high dynamics of working movements, positioning accuracy and excellent rigidity.

CNC lathe machines– machines designed for medium and large-scale production. They are perfect for making elements with complex shapes and those that require special precision. The objects processed in them are characterized by high quality of workmanship.

TECHNICAL DATA

| CNC LATHE | maximum rolling diameter: Ø 300 Spindle clearance: Ø52 |

| CNC LATHES | Maximum rolling diameter: Ø 38 |