COOPERATION

CUTTING

(laser)

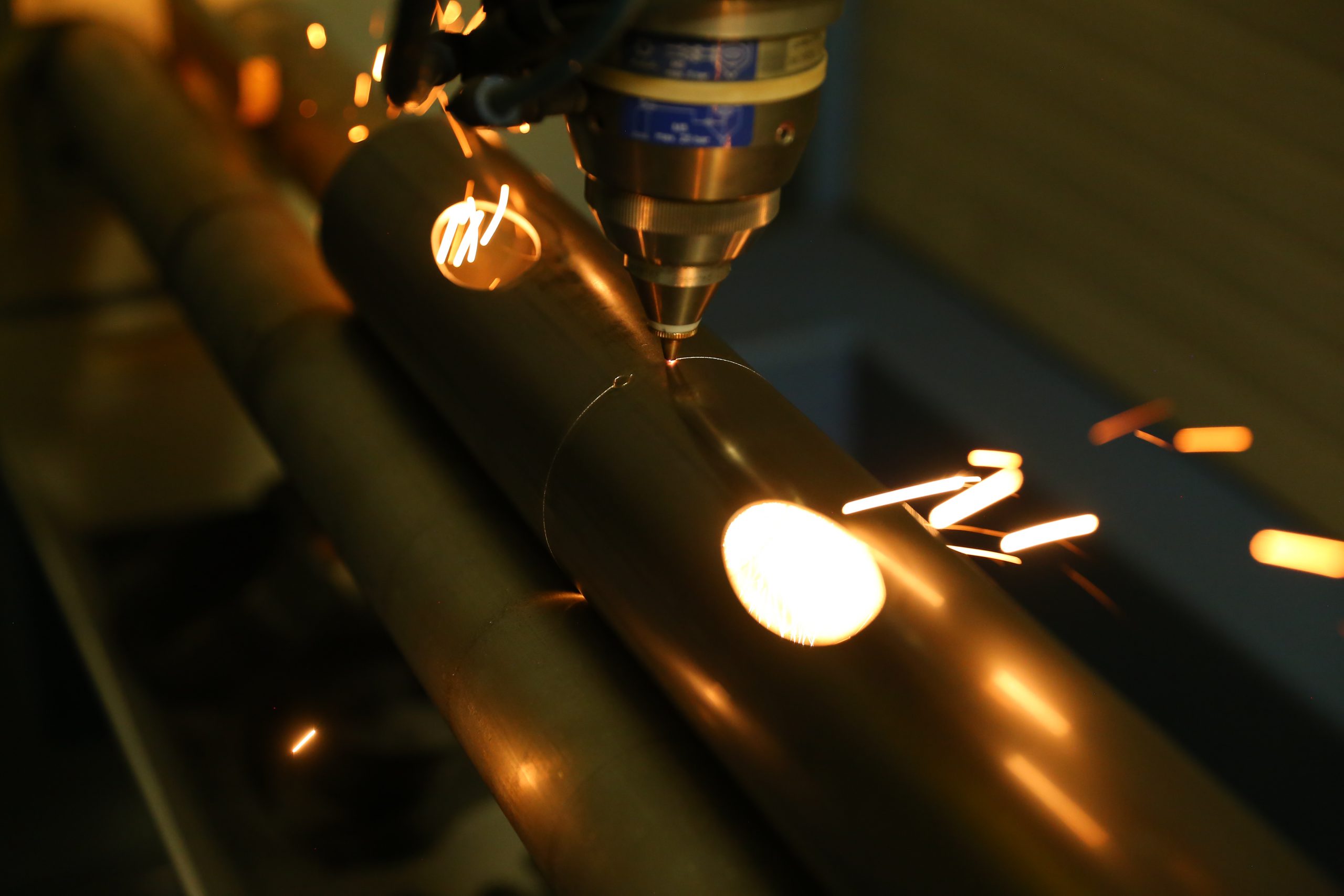

Laser cutting is a technology for efficient cutting of materials, which consists in the generation of a large amount of energy by the laser radiation generator, focused on a small area.

LASER CUTTING

Laser beam cutting takes place over a very small, precisely defined area. The final products are characterized by a very high quality of the edges (without any additional processing) and, most importantly, 100% repeatability.

We use laser cutting:

The CO2 type laser gives the possibility to cut a variety of materials using a laser beam that is generated in the carbon dioxide medium. Cutting with a CO2 laser is characterized by a very small heat affected zone and a relatively narrow cutting gap. The fired elements are characterized by clean and perpendicular edges and small irregularities of the separation surface.

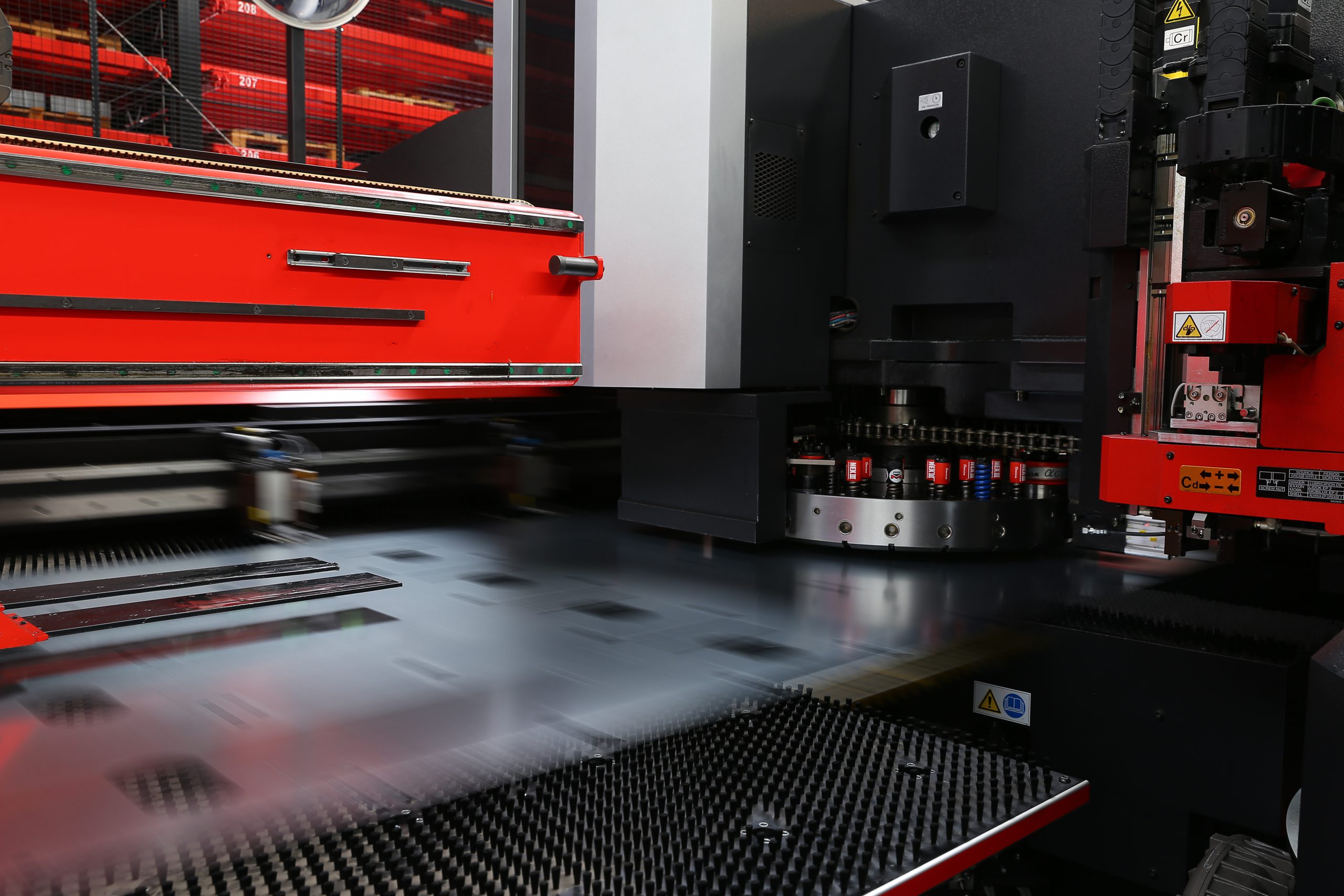

Fiber technology is a solution that has revolutionized the laser cutting market. Compared to CO2 technology, it is much faster and allows to achieve much better results, especially very dynamic and fast cutting of thin sheets. In addition, Fiber technology provides the highest dimensional accuracy by eliminating burrs and the absence of material overheating.

CO2 TYPE LASER

| TYPE OF MATERIAL | Black steel, stainless steel, galvanized sheet metal, aluminum, |

| THICKNESS OF CUT MATERIAL | 0,5 mm – 5 mm |

| DIMENSIONS OF THE MATERIAL TO BE PROCESSED | 1500 x 3000 mm |

| ACCURACY OF CUT | +/- 0,1 mm |

FIBER TECHNOLOGY

| TYPE OF MATERIAL | Black steel, stainless steel, galvanised sheet metal, aluminium, copper, brass |

| THICKNESS OF CUT MATERIAL | 0,5 mm – 5 mm |

| DIMENSIONS OF THE MATERIAL TO BE PROCESSED | 1500 x 3000 mm |

| ACCURACY OF CUT | +/- 0,1 mm |