03.02.2020

CUTTING

COOPERATION

CUTTING

Punching is the process of cutting out from sheet metal of any shape, by means of a tool called a punch, which is a reflection of the shape of the element being obtained.

The punching technology allows to shape simple elements and the most complex ones requiring high dimensional accuracy. The process allows to produce a large number of elements in a relatively short time.

WE USE TO CUTTING:

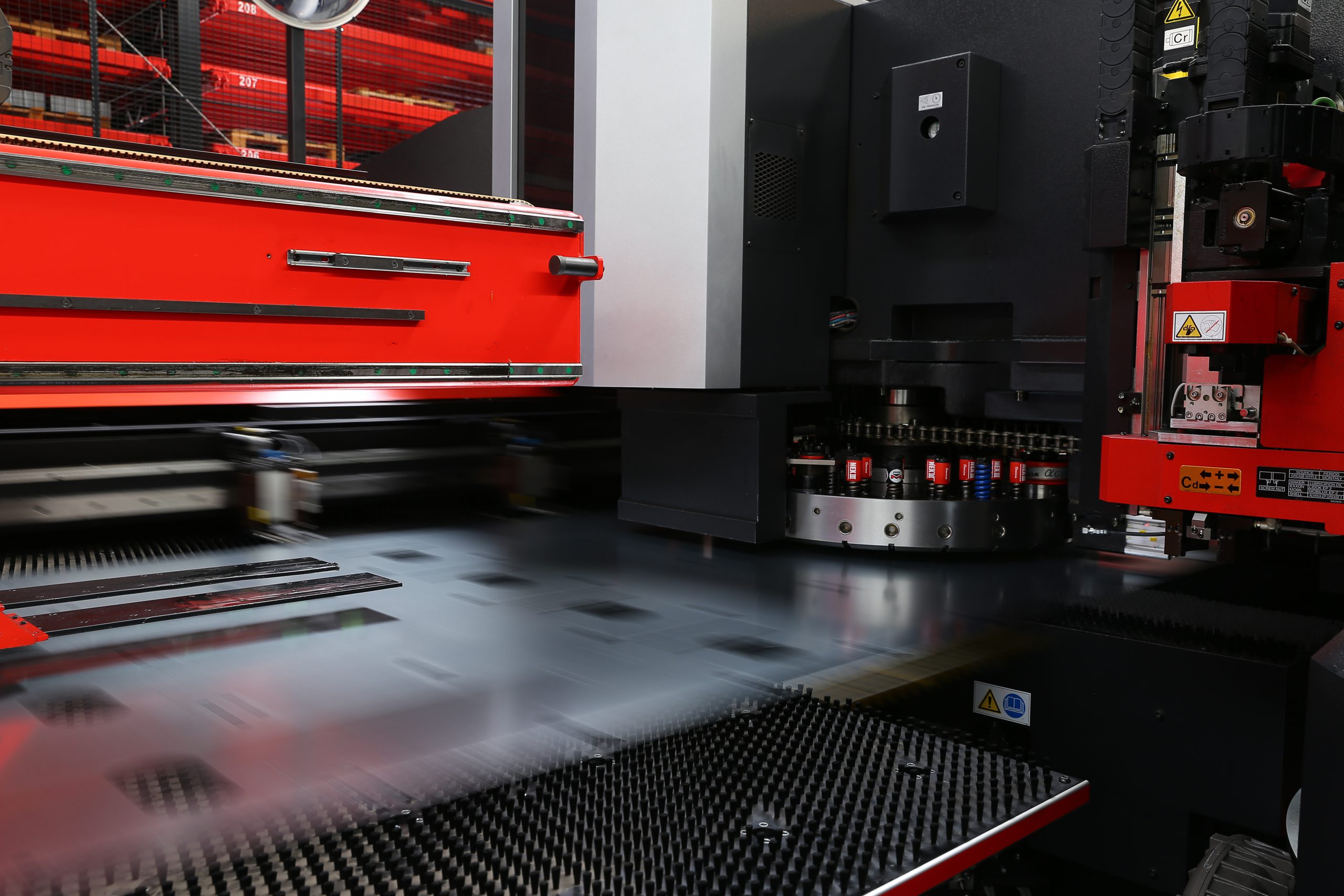

The AMADA AC 2510 NT– punching machine – has a brush table that prevents scratches. The punching force is up to 200 kN. The punching machine is characterized by high positioning and punching speeds, which translates directly into high performance.

The AMADA EM 3612 ZRT– punching machine is equipped with an automatic tool changer, which ensures maintenance-free and thus extremely efficient production, using several hundred tools. Thanks to the use of a brush table, the risk of sheet metal scratches is eliminated.

AMADA AC 2510 NT punching machine

| TYPE OF MATERIAL | Black steel, stainless steel, galvanized sheet metal etc. |

| THICKNESS OF CUT MATERIAL | 0,5- 2 mm |

| DIMENSIONS OF THE MATERIAL TO BE PROCESSED | 2500 x 1270 mm |

| POSITIONING ACCURACY | +/- 0,1 mm |

AMADA punching machine EM 3612 ZRT with automatic tool changer

| TYPE OF MATERIAL | Black steel, stainless steel, galvanized sheet metal etc. |

| THICKNESS OF CUT MATERIAL | Max. 3 mm |

| DIMENSIONS OF THE MATERIAL TO BE PROCESSED | 1500 x 3000 mm |

| POSITIONING ACCURACY | +/- 0,1 mm |