For almost three decades, DARCO has been developing its range of sheet metal products and thus building relationships based on trust and reliability. A solid infrastructure enables us to take on new challenges. DARCO has two production halls with a total production area of 14,000 m2. Equipped with modern technology including fully robotized stations, 2D and 3D laser cutting machines, CNC machining centres and our own laboratories, we constantly use them for product improvement and testing. The Logistics Centre has an area of over 8000 m2.

DARCO provides high quality cooperation services for HVAC, construction, electronics, engineering, automotive, storage and interior design industries based on its extensive machine, logistics and research facilities. Our activities consist of.

Creation of concepts: technical advice, conceptual modelling, preparation of technical documentation and making a prototype.

Production: with the use of experience and the latest machines we offer services: cutting, forming, machining, joining and assembly, machining.

Logistics service: picking, packing, storage, shipping and transport

You are welcome to address inquiries: kooperacja@darco.pl

CUTTING

Treatment consisting in cutting out shapes of any size and form in sheet metal.

FORMING

Giving flat sheet metal parts a three-dimensional shape.

MACHINING

Shaping the elements by removing overburden layers.

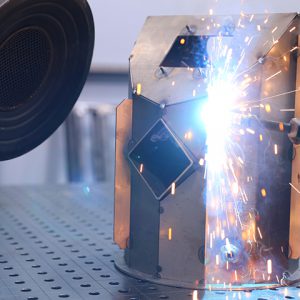

JOINING AND ASSEMBLY

Combining metal parts using modern, precise tools.

Surface treatment

Protecting products against harmful conditions and giving them the desired structure and colour.

Download the DARCO cooperation folder: